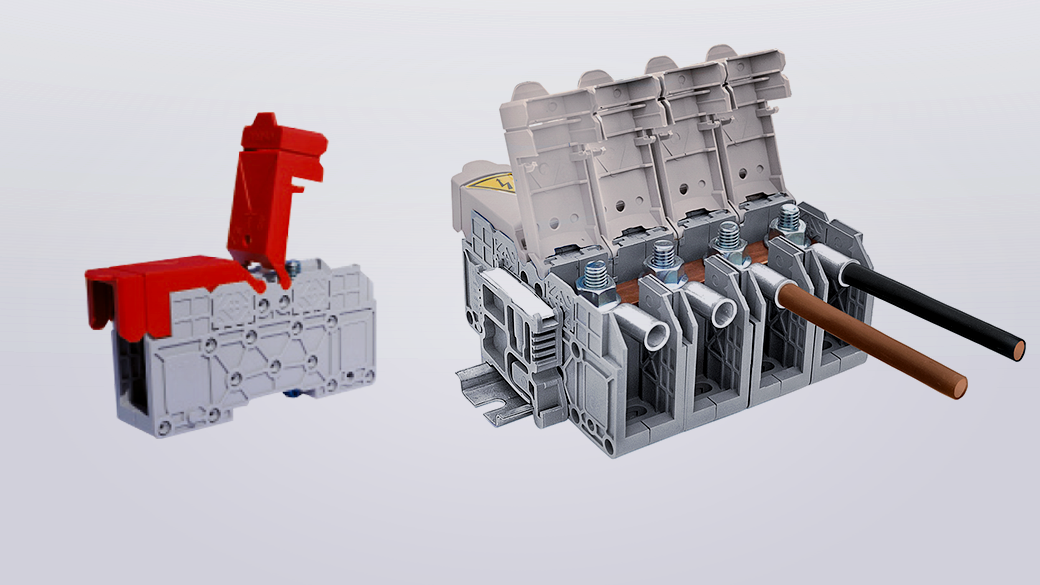

Stud Terminal Blocks – MRK

Product detail

Screwed Type Stud Terminal Blocks are more reliable when connection is in vibrating environments. Screwed Type Stud Terminal Blocks are preferred in three-phase systems as it is a healthier way of connection.

SKP lug is first screwed to high-profile cable end steadily in Screwed Type Terminal Blocks. That SKP lug is fitted to terminal block according to defined torque value. Thus, two conductive surfaces contact each other. Since two contacting conductive surfaces have more space in Screwed Type Stud

Terminal Blocks, it is suitable for use in high currents. Terminal blocks for 25 mm 2, 35 mm 2, 50 mm 2, 70 mm 2, 95 mm 2, 120 mm 2, 150 mm 2, 185 mm 2 and 240 mm 2 profile cables are in production.

Thickness of copper busbar inside terminal block varies proportionate to cable profile only. Thickness of copper busbar in defined in line with maximum current that cable profile in use is supposed to carry and based on international standards. Thus, it is safe to use in high currents.

Disconnection due to vibration in environments with vibration is not seen in Screwed Type Stud Terminal Blocks as the connection is screwed strongly with a nut. For this reason, it is the top choice of machinery manufacturers when connecting three phases.

They are also widely used in railway sector, air-conditioning systems of train and subway cars, maritime sector, in engine rooms of ships, and any

other environments with vibration.